Products

Categories

Top Products

Three-Phase Asynchronous Motor CRM

Explosion-Proof Asynchronous Motor

Permanent Magnet Synchronous Motor (PMSM)

Brushless DC Motor with Encoder

DC Servo Motor for Industrial Automation

High-Precision Stepper Motor

Top Products

Permanent Magnet Synchronous Motor (PMSM)

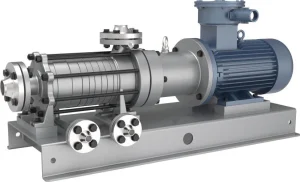

BM(B) Series Insulated Magnetic Drive Centrifugal Pump Product Description The BM(B) and BM(BB) series are two types of insulated magnetic drive centrifugal pumps developed by our company to meet market demands for conveying constant-temperature media. These magnetic pumps can transport both...

Product Title

Permanent Magnet Synchronous Motor (PMSM)

Production Details

The BM(B) and BM(BB) series are two types of insulated magnetic drive centrifugal pumps developed by our company to meet market demands for conveying constant-temperature media. These magnetic pumps can transport both high-temperature and low-temperature media, with the requirement that the conveyed medium must remain within the specified temperature range. Featuring a unique insulated casing structure, these pumps maintain the required operational temperature during media transfer while preventing crystallization, condensation, viscosity changes, or vaporization due to temperature fluctuations. Depending on specific working conditions, the insulated magnetic pumps employ appropriate heating/cooling methods for wetted parts to ensure material performance remains unaffected by environmental temperature.

BM(B) Series Insulated Magnetic Drive Centrifugal Pump

The BM(B) series utilizes a jacketed insulation structure for the pump body and cover, typically suitable for media with small temperature differences between ambient and specified temperatures. It offers advantages of simple structure and low manufacturing cost.

BM(BB) Series Insulated Magnetic Drive Centrifugal Pump

The BM(BB) series employs a 360° dead-angle-free fully jacketed structure design, suitable for media with significant temperature differences between ambient and specified temperatures (such as phthalic anhydride). Its characteristics include excellent thermal insulation effect and high efficiency. The magnetic drive system uses Sm2Co17 high-temperature samarium-cobalt rare earth alloy material, with an operating temperature range of -90°C to 350°C.

Magnetic Drive Features

- The inner and outer magnetic rotor assemblies are installed in opposite directions with the isolation sleeve, achieving an internal magnetic drive with jacketed coating on the isolation sleeve. This design ensures truly 360° dead-angle-free insulation, providing complete thermal protection for pump components, enhancing insulation effectiveness and efficiency, and effectively addressing issues of insufficient insulation and low thermal conductivity.

- Auxiliary blades on the inner magnetic rotor base provide power for internal media circulation. The pressurized circulation ensures adequate cooling and lubrication of the system even for special media with high melting points or high viscosity.

- A rear drain port is provided at the lowest position of the isolation sleeve, allowing users to remove residual material from the pump's rear chamber, facilitating long-term stable operation of the insulated magnetic pump.

Main Technical Parameters

Main Technical Parameters

Common Materials Of Motor

Cooper

Copper can be drawn into flat shapes to form rectangular winding wires. Rectangular winding wires are integral components in compact and high-performance applications like electric vehicle motors, EV power trains etc.

Steel

Silicon steel offers good shielding properties against electromagnetic interference. Therefore, it is useful in equipment where the radiation needs minimizing, such as medical instrumentation or transport systems like railroads.

Cast Iron

Cast iron is a good choice for an engine block. It is easily sand cast, easy to machine, capable to resist piston wear quite well, and inexpensive as a material.

Silicon steel sheet

The silicon steels are produced in two forms, highly textured grain-oriented alloys and alloys in which the grains are not oriented. Grain orientation is carried out to align the magnetic easy axis.